Absolutely tight, versatile, durable and safe

-

Reliably tight - even in harsh industrial environments

- Due to the triple offset disc design (maximum closing force with minimum effort)

- Due to the “smart” sealing ring (uniform closing force because the ring is self-aligning and free-floating on the sealing surface)

- Due to the laminated stack of the elastic, stainless steel / graphite sealing ring

- Due to a wide range of additional safety options

- Due to the stellited seat (Stellite No. 21)

- Due to the metal seal principle

-

Performance features at a glance

Maximum closing force with minimum effort because the contact angles are optimised with our special geometry optimisation software.

Maximum closing force with minimum effort because the contact angles are optimised with our special geometry optimisation software. Self-aligning sealing ring facilitates thermal compensation and ensures leak-tightness regardless of temperature variations.

Self-aligning sealing ring facilitates thermal compensation and ensures leak-tightness regardless of temperature variations. Laminated stack made of stainless steel and graphite lends additional elasticity to the sealing ring. Double sealing mechanism in the form of a special, spiral-wound gasket made from a heat-resistant elastic material.

Laminated stack made of stainless steel and graphite lends additional elasticity to the sealing ring. Double sealing mechanism in the form of a special, spiral-wound gasket made from a heat-resistant elastic material. Triple offset design guarantees a frictionless swivel movement of the sealing ring into the seat.

Triple offset design guarantees a frictionless swivel movement of the sealing ring into the seat. The ZETRIX® process valve seals according to the area seating principle; the required contact pressure is applied via the actuator, which can be switched off as a function of the torque.

The ZETRIX® process valve seals according to the area seating principle; the required contact pressure is applied via the actuator, which can be switched off as a function of the torque. The ZETRIX® process valve is extremely versatile. It can be used as a pipe-end valve on both sides. The bracket for mounting the actuator is defined according to ISO 5211. The neck length allows insulation thicknesses in line with industrial standards.

The ZETRIX® process valve is extremely versatile. It can be used as a pipe-end valve on both sides. The bracket for mounting the actuator is defined according to ISO 5211. The neck length allows insulation thicknesses in line with industrial standards. Optimal durability because even the standard version has a stellited seat.

Optimal durability because even the standard version has a stellited seat.

-

Technical profile

- Design EN 12516, ASME B16.34, API 609

- Type of connection EN 1092, ASME 16.5, ASME 16.47

- Nominal diameter

Double flange: DN 80-1200, 3" - 48"

Lug type: DN 80-600, 3" to 24"

butt-weld ends: DN 80-600, 3" to 24" - Nominal pressure PN 10 to PN 100, Class 150, Class 300 / 600

- Face-to-face

Double flange: DIN EN 558-1 series 13, ISO 5752, API 609

Lug type: DIN EN 558-1 series 16, ISO 5752

Butt-weld ends: DIN EN 558-1 series 14, ISO 5752 - Material Cast steel (1.0619 +N; SA216 WCB) Stainless steel (1.4408; SA351 CF8M)

- Temperature -60°C to +427°C

- Flow media liquids, gases, vapours

- Actuators Manual gearbox, pneumatic, electric, hydraulic drives

- Approvals firesafe, SIL, ATEX, ISO 15848-1, ATEX

- Typical applications Oil and gas processing, refineries, petrochemicals, chemicals, power plants, district heating, solar thermal power stations, pulp and paper, steelworks, sugar processing, industrial and plant manufacturing

- Other designs on request

-

Modern development methods

Finite element method

Finite element method

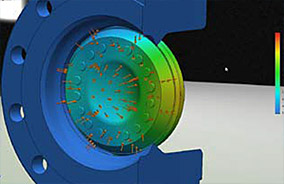

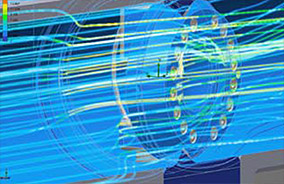

The finite element method (FEM) is a numerical calculation technique that was used to simulate the stresses and their distribution occurring in the ZETRIX® process valve. The aim was to achieve the required strength at pressure load levels in combination with an optimal weight and a flow friendly shape. State-of-the-art flow simulations

State-of-the-art flow simulations

The twofold objective of uniform flow and high flow capacity was realised with the aid of special flow software. The software simulations enable the flow velocity, flow direction and pressure distribution to be visualised. Due to the optimised ZETRIX® geometry, turbulences are reduced to a minimum and pressure loss optimized. Rigorous tests

Rigorous tests

“Firesafe” is a basic stipulation in many of the environments where the ZETRIX® process valve is used. As a triple offset 90° process valve with a tight metal seal, ZETRIX® meets all requirements before, during and after the fire. The test was performed according to ISO 10497, API 607 6th Edition Characteristic measurements

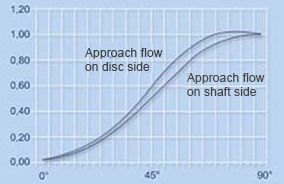

Characteristic measurements

The flow values at different opening angles were measured in an accredited testing laboratory. The resulting curves were used to determine the control characteristic of the ZETRIX® process valve. Contact angle calculation

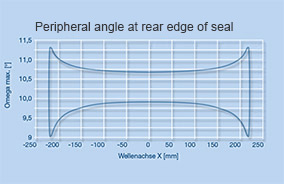

Contact angle calculation

The peripheral closing angle was optimised to ensure that the valve opens and closes without sticking and without friction. Our sizing software allows the contact angle at the perimeter of the ZETRIX® process valve seat to be visualised.

-

High-precision manufacturing

The valve bodies are manufactured on fully automatic, CNC controlled machining centres. Our CNC programs are written on the basis of CAD data and transferred to the control online. The workpieces are clamped in specially designed fixtures that guarantee maximum machining stability and short set-up times.

The valve bodies are manufactured on fully automatic, CNC controlled machining centres. Our CNC programs are written on the basis of CAD data and transferred to the control online. The workpieces are clamped in specially designed fixtures that guarantee maximum machining stability and short set-up times. The sealing surface is armoured with Stellite® by a fully automatic welding robot with an integrated measuring system. All CNC programs are developed by our expert in-house programmers. Synchronising the eight axes of the welding system represents a particularly challenge.

The sealing surface is armoured with Stellite® by a fully automatic welding robot with an integrated measuring system. All CNC programs are developed by our expert in-house programmers. Synchronising the eight axes of the welding system represents a particularly challenge. The three-dimensional measuring system allows the process valves to be compared with 3D data, which is subsequently evaluated and saved on a PC. The measurements are carried out directly in the machine to ensure reliable production processes.

The three-dimensional measuring system allows the process valves to be compared with 3D data, which is subsequently evaluated and saved on a PC. The measurements are carried out directly in the machine to ensure reliable production processes. Every ZETRIX® process valve is leak-tested according to DIN EN 12266. The test pressures and times are stored on our computer aided test bed. Special tests can also be performed at the customer’s request.

Every ZETRIX® process valve is leak-tested according to DIN EN 12266. The test pressures and times are stored on our computer aided test bed. Special tests can also be performed at the customer’s request.

-

Design

- Body acc. to EN12516, ASME B16.34 and API 609

- Tight metal shut-off

- Triple offset sealing geometry

- Flexible, self-aligning, laminated metal sealing ring (floating)

- Optimised characteristic permits shut-off and control function

- Neck length suitable for pipe insulation from -60°C to +400°C

- Easy to automate due to the actuator interface incl. position indicator to ISO 5211

- Durability

-

Safety

- Tightness conforming to leakage rate A in accordance with EN 12266, API 598 and API 6D (bidirectional)

- Sealing ring protected against rotation

- Bearing protectors

- Blow-out protected stem

- Retaining ring and thrust bearing bolts locked

- Pressure-temperature profile acc. to EN 1092, ASME B16.34

- Approvals: Firesafe, TA-Luft / ISO 15848-1, SIL, ATEX

-

Options

- Flushing port for the shaft bearings and buffer port for protecting the stuffing box

- Flushing port for the bottom flange

- Welded bottom flange

- Double packing with drainage line (e.g. for thermal oil services)

- Test port

- "Clean air" bushing acc. to TA-Luft / ISO 15848

- Solid sealing ring for special applications

- Heating / cooling jacket

- Blow-out protection acc. to API 609

-

Video: Quick closing in 0,6 sec

-

Please to watch this video.

-

ARI-Armaturen Albert Richter GmbH & Co. KG

ARI-Armaturen Albert Richter GmbH & Co. KG